Features:

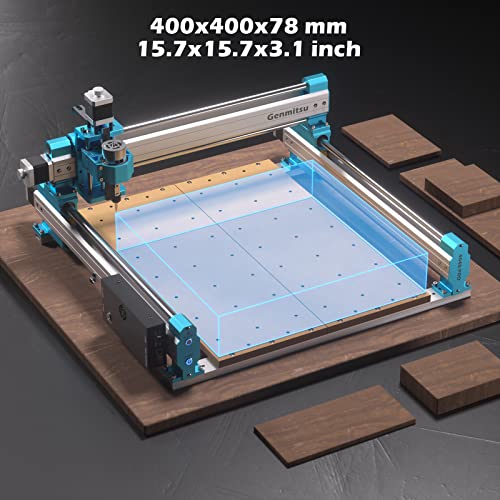

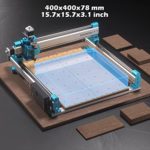

- An effective working area of 15.7” x 15.7” x 3.1” is large enough for most daily wood carving projects. The redesigned Z-axis carriage makes swapping a spindle easier. Adding more screw holes on the non-all-in-one Z-axis carriage allows you to install the larger spindle higher for extra overfeed height.

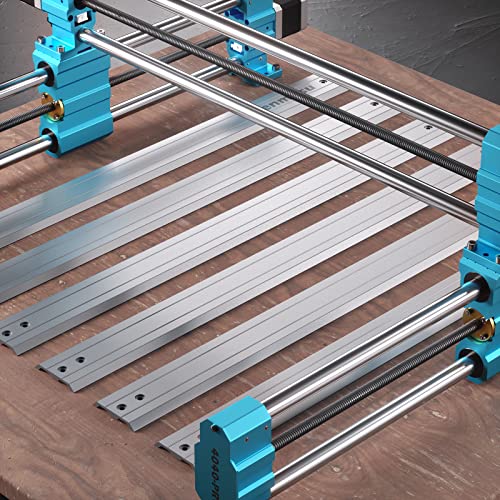

- New Steel HSS Frame – all new redesigned frame structure, each axis is composed of two 16mm Steel HSS linear tubes and a lead screw motion drive, dual Y axis rails, and all metal frame. This new high-rigidity structure ensures the stability and accuracy of the milling machine.

- Still based on open-source Grbl v1.1, the 4040-PRO CNC router has stepped up to more powerful but silent Toshiba TB6S109 drivers with 32-bit chips. Upgrades include extended function ports like a dedicated 3 Pin Laser Port, Air Assistance Pump Port, and MPG Port.

- All main parts are pre-assembled and it just takes about 15 minutes to finish the whole machine assembly. The spoilboard is combined by two pieces of MDF boards. Each MDF board could be replaced individually. You don’t need to replace the whole spoilboard when a panel gets damaged.

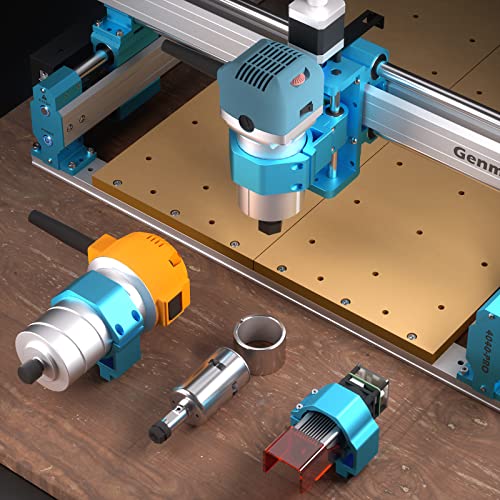

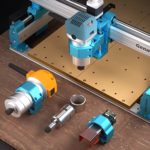

- The 4040-PRO CNC machine is supplied with 42mm and 52mm spindle mounts. The additional 65mm (B0BRZSY475), 69mm (B0BRZSVVK3) spindle mount, laser module, and other upgraded accessories are available to order. You can easily upgrade the machine according to your needs. If you get stuck, check out the SainSmart Resource Centre (see User Guide) or contact us with any questions you may have.

- It supports adding the 4th-axis rotary module kit. The 4th-axis kit enables your 4040-PRO desktop CNC to carve from different angles and positions or with the right software full 3D rotary caving.

Reviews

There are no reviews yet.